Products

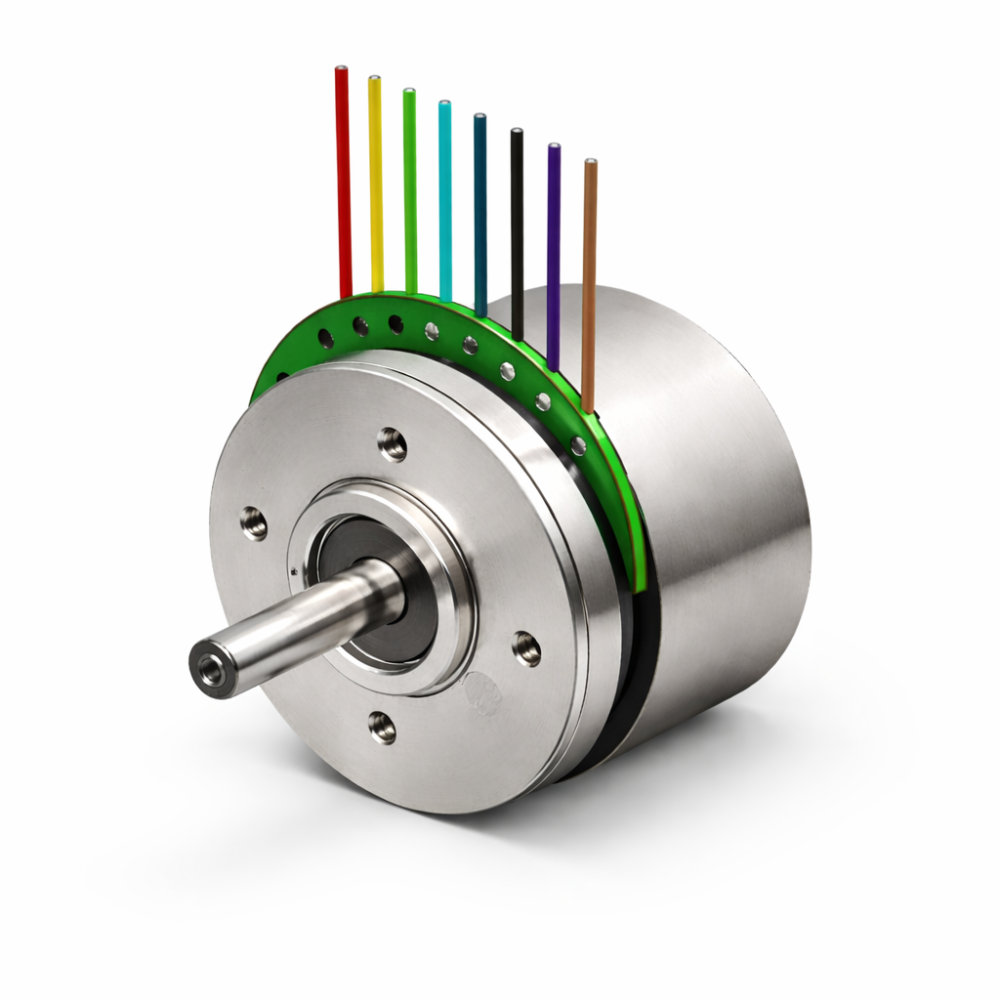

BRUSHLESS DC MOTOR (bldc)

BLDC Motor

| Specification Ranges | |

|---|---|

| Diameter | 20mm (Min) to 350mm (Max) |

| Length | 30mm (Min) to 350mm (Max) |

| Nominal Torque | 0.05Nm to 500 Nm |

| Max Permissible Speed | 50RPM to 30,000 RPM |

BRUSHLESS DC MOTOR (bldc)

BLDC SLOTLESS MOTOR

| Specification Ranges | |

|---|---|

| Diameter | 4mm (Min) to 60mm (Max) |

| Length | 20mm(Min) to 68mm (Max) |

| Nominal Torque | 1mNm to 25mNm |

| Max Permissible Speed | 2,00,000 RPM |

BRUSHED DC MOTOR (bdc)

BDC MOTOR

| Specification Ranges: | |

|---|---|

| Motor Diameter | 20mm (Min) to 220mm (Max) |

| Length | 28mm (Min) to 95mm (Max) |

| Nominal Torque | 1mNm to 35 Nm |

| Max Permissible Speed | 20,000 RPM |

| Grade | Aerospace and Industrial Grade |

| Qualification | As per Customer requirements |

|

Applications: Drones, Robotics, Pumps, Fans, Actuators, Power tools, Automation, Aerospace, Toys, Sensors, etc. |

|

BRUSHED DC MOTOR (bdc)

BDC SLOTLESS (Miniature) MOTOR

| Specification Ranges: | |

|---|---|

| Motor Diameter | 6mm (Min) to 36mm (Max) |

| Length | 15mm (Min) to 98mm (Max) |

| Nominal Torque | 1mNm to 120mNm |

| Max Permissible Speed | 70,000 RPM |

| Grade | Aerospace and Industrial |

| Qualification | As per Customer requirements |

|

Applications: Surgical tools, Surgical Robotics, Infusion pump, Aerospace (Seat Actuators, Cockpit Automation), precision actuator, Consumer Electronics, Micro Drones, Industrial automation, etc. |

|

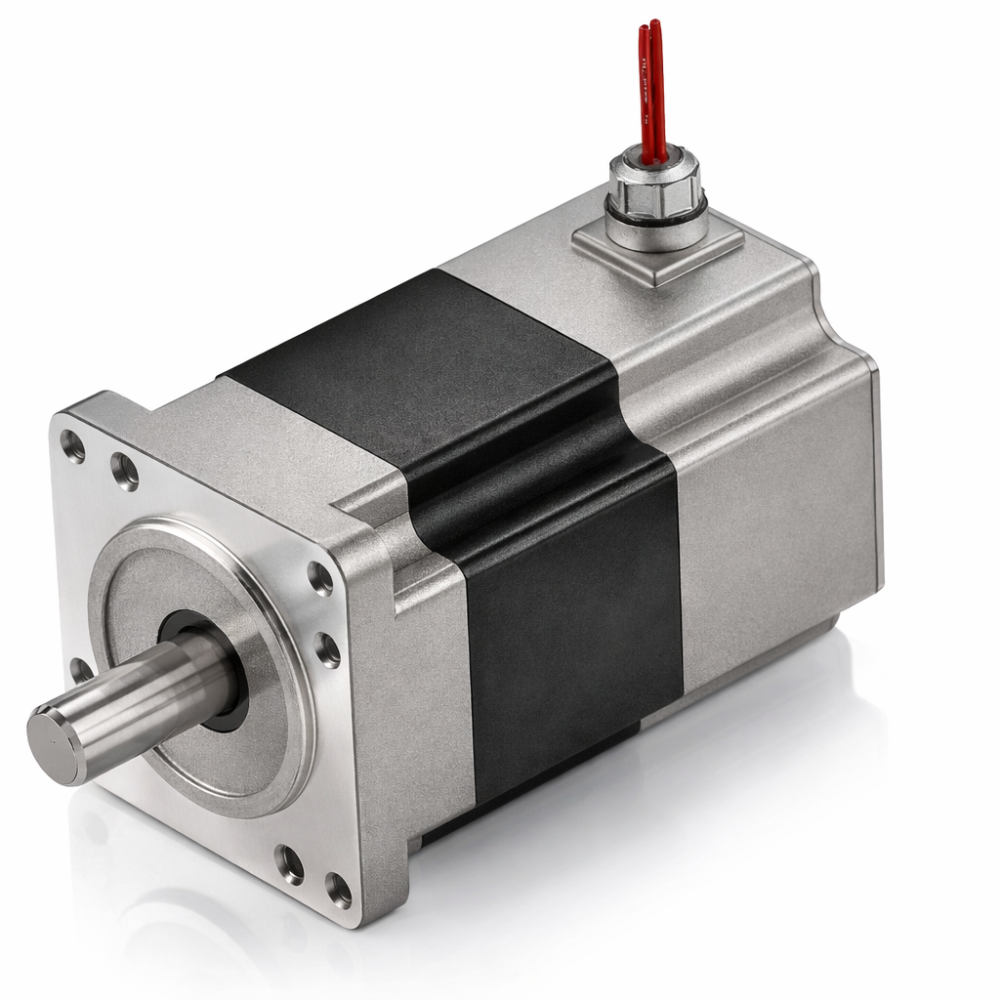

STEPPER MOTOR

hybrid stepper motor

| Specification: | |

|---|---|

| Motor Diameter | 48mm (Min) to 85mm (Max) |

| Length | 24mm (Min) to 102mm (Max) |

| Holding Torque | 0.1Nm to 4 Nm |

| Step Angle | 0.9° & 1.8° |

| No. of Steps / Sec | 250 to 2400 |

| Winding Type | Simplex, Duplex and Triplex |

| Grade | Aerospace and Industrial Grade |

|

Applications: Aerospace, Robotics, Industrial Machinery, Automation, Consumer Electronics, etc. |

|

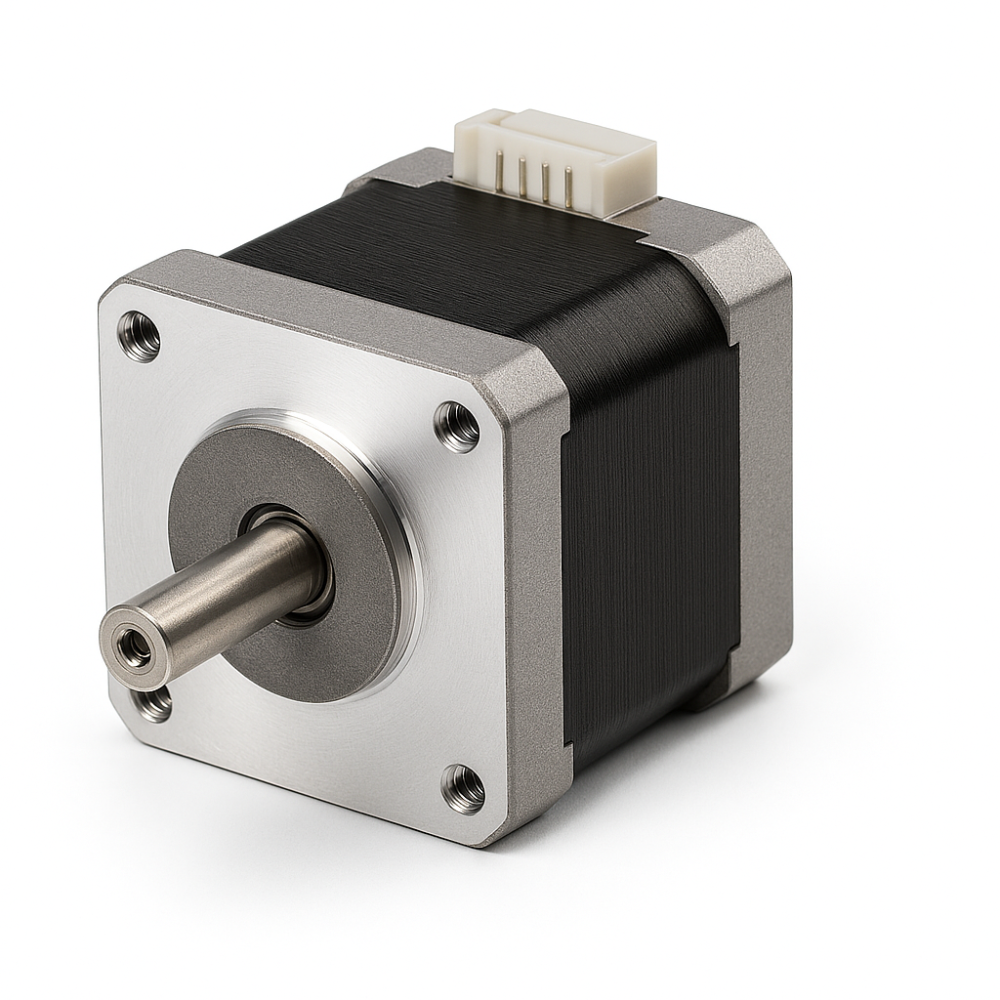

STEPPER MOTOR

CAN STACK STEPPER MOTOR

| Specification: | |

|---|---|

| Motor Diameter | 15mm (Min) to 69mm (Max) |

| Length | 10mm (Min) to 50mm (Max) |

| Torque | 3mNm to 169mNm |

| Step Angle | 7.5°, 15°, 18° & 24.5° |

| No. of Steps / Sec | 20, 24, 48 & 100 |

| Winding Type | Simplex & Duplex |

| Grade | Aerospace and Industrial Grade |

|

Applications: Printers & Scanners, Clinical Diagnostic Equipment, Consumer Electronics, Aerospace, Robotics, Industrial Machinery & Automation, etc. |

|

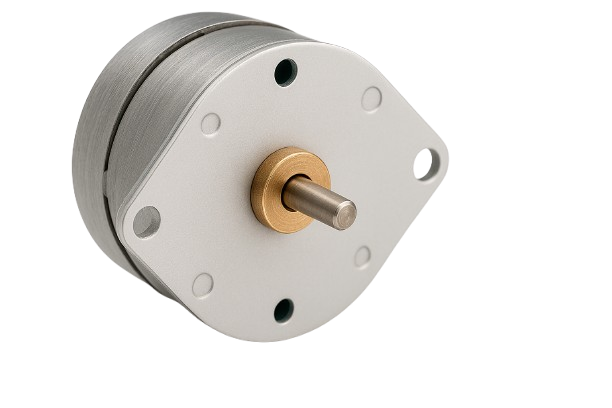

FLAT MOTOR

HALBACH ARRAY MOTORS

| Specification: | |

|---|---|

| Motor Diameter | 20mm (Min) to 200mm (Max) |

| Length | 10mm (Min) to 40mm (Max) |

| Torque | 9mNm to 50Nm |

| Grade | Aerospace and Industrial Grade |

|

Applications: Compact Devices, Drones, Industrial Automation, Robotics, Aerospace, Surgical Robotics, etc. |

|

Common questions answered

Frequently asked questions

Browse this section for clear information about Aeterniq Advanced Motor Solutions, our approach, and what you can expect as a client partnering with us.

Do you offer custom motor design and development?

Yes. Custom motor design is our core strength. We work closely with customers to meet specific requirements such as torque, speed, power, size, weight, efficiency, thermal limits, and environmental conditions.

Can you support prototype development and low‑volume production?

Absolutely. We support concept validation, prototyping, testing, and low‑volume production, with scalability for future volume requirements.

Are you open for standalone design projects?

Yes. In addition to development support, we offer standalone motor design services for R&D and advanced engineering applications.

Do you work with startups, R&D teams, and government agencies?

Yes. We actively collaborate with startups, research organizations, and government agencies, including strategic and mission‑critical projects.

What quality standards do you follow?

We adhere to stringent internal quality and testing procedures. Based on customer specifications and critical application requirements, our motors are thoroughly validated for performance, reliability, and safety. Certification and compliance support are provided as per project and regulatory requirements.

What is the typical lead time for development and delivery?

- Concept & design: 2–6 weeks

- Prototype development: 4–8 weeks

- Production: Based on quantity and specifications

What is the minimum order quantity (MOQ)?

MOQ varies based on motor type and customization level. For R&D and prototypes, we offer flexible quantities.

Are your motors suitable for space or high‑reliability applications?

Our motors are designed with reliability, precision, and efficiency in mind, making them suitable for high‑reliability and mission‑critical applications, subject to application‑specific validation.

How can I share my technical requirements?

You can contact us via our website, email, or phone. Our engineering team will review your requirements and initiate discussions.